Pallet Machinery

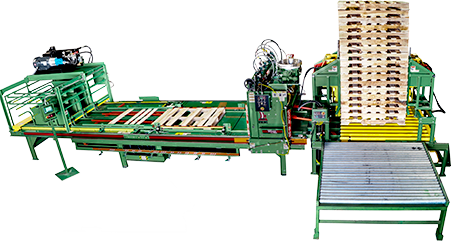

Viking automated pallet equipment is engineered with innovative electrical, mechanical, hydraulic and PLC control components, representing state-of-the-art technology. Known for their dependability and performance, Viking nailing machines have been the go-to nailer in pallet manufacturing for over 45 years.

All Viking nailing machines offer versatility by producing many different pallet types with some Viking pallet nailing equipment capable of using recycled lumber.

Proven quality, continuous innovation and unmatched service and support, you can trust Viking for your wood pallet manufacturing needs.

Voyager

Turbo 606

The Turbo 606 Pallet Nailer introduces the latest in remote monitoring technology, this allows for real-time machine production data to be accessed via many devices. Teamed with the latest technology and quickest changeovers, the 606 has the capability of building upwards of 2000+ pallets/shift with three operators. Engineered for reliable performance and longevity, the 606 offers the best combination of speed and innovation to take your pallet business to the next level.

Turbo 505 SE

The Turbo 505 Silver Edition provides an up to 15% improvement in cycle time, advanced operator screen settings and an extended M2 catwalk compared to the standard Turbo 505. Engineered to provide high output, low maintenance, and quick changeovers with fast mechanical setup (FMS), while only requiring three operators. Powered by the Turbo Pro Plus Data software, machine operators can monitor real-time information to make better decisions improving quality production and efficiency.

Express 403

With production capabilities upwards of 1,300 pallets/shift with 2 operators, the Express 403 Pallet Nailer is the newest addition to the Viking lineup. Providing consistent output and low maintenance, the 403 is the industry’s most economic tandem option. Powered by the Turbo Pro software, machine operators can integrate with 3rd party design software and create their own pallet specifications to improve quality production.

Champion QC306

With the ability to use recycled and low grade lumber, the Champion QC306 Pallet Nailer is a single operator system that produces upwards of 500-600 pallets/shift. The flexibility of the QC306 Pallet Machine allows for optional mat and block production capabilities, extended pallet sizes, and quick changeovers. Containing the most versatile features and functions, the QC306 allows your business to thrive in times of market volatility.

Champion 304A Classic

The Champion 304A Classic is a single operator pallet nailing system capable of producing upwards of 500 pallets/shift. As the best valued Champion, the 304A Classic continues to provide recycled and low grade lumber capabilities, durability, and pallet sizes up to 72 x 60 inches (60 x 60 inches standard). With optional mat and block kits, the 304A Classic pallet machine will keep you ahead of changing market demands.

Used Equipment Listings

Viking assists customers in selling their used pallet machinery. We can leverage our database of pallet manufacturers to help you buy or sell your used pallet equipment.

Used Equipment Listings are an Advertising Service

Used Equipment Listings are an online advertising service for Viking Engineering customers. Viking does not sell the used equipment listed directly and is never a party to any transaction between buyers and sellers. Viking does not (a) guarantee or ensure any equipment or transaction between buyer and seller, (b) make any claims to the current state or condition of the used equipment, (c) collect or process payment on behalf of buyers or sellers, or (d) warehouse, store, ship or deliver the used equipment listed (unless otherwise agreed upon).