Equipment

Automated Wood Fastening Solutions

Viking Engineering and Development has been the most trusted partner in the automated wood fastening industry since 1975. Our Viking family is personally invested in the success of our customers. As the industry leader with a global presence, Viking's commitment to providing a genuine customer experience and quality products takes their business to the next level.

We take pride in providing industry leading technology, innovation and service and have done so since 1975. As an ISO Certified manufacturer, we hold ourselves to the highest of quality standards. This commitment to quality is reflected in the longevity of our automated wood fastening equipment.

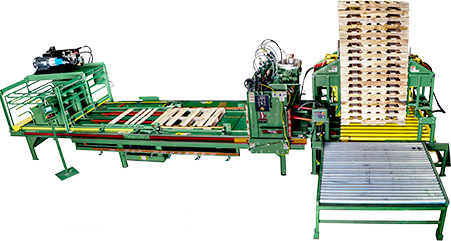

Pallet Machinery

Viking automated pallet equipment is engineered with innovative electrical, mechanical, hydraulic and PLC control components, representing state-of-the-art technology. Known for their dependability and performance, Viking nailing machines have been the go-to nailer in pallet manufacturing for over 45 years.

All Viking nailing machines offer versatility by producing many different pallet types with some Viking pallet nailing equipment capable of using recycled lumber.

Proven quality, continuous innovation and unmatched service and support, you can trust Viking for your wood pallet manufacturing needs.

Bedding Automation

Viking Engineering and Development’s automated bedding machinery creates revolutionary solutions for bed frame assembly and wooden box spring assembly manufactures. Sprint and Skute nailing machines optimize wooden beam and foundation assembly processes through automation that create a more consistent final product, reduce labor costs, and improve workplace safety.

Viking Engineering has been the most trusted partner in the automated wood fastening industry since 1975. The Viking family is dedicated to earning the business of our customers by delivering proven quality, continuous innovation with unmatched service and support.

Bulldog Band Chopper

Heavy duty and reliable, the Bulldog Band Chopper is a scrap chopping workhorse. This scrap chopper is capable of chopping plastic straps, metal banding as well as thin saw blades like doctor blades.

The Bulldog banding chopper helps reduce dumpster expense, improve employee safety, and keeps workplaces clean. Reach your company's zero-waste and recycling goals by generating revenue from your scrap material processing.

Request a Quote and Order your Bulldog Band Chopper today!